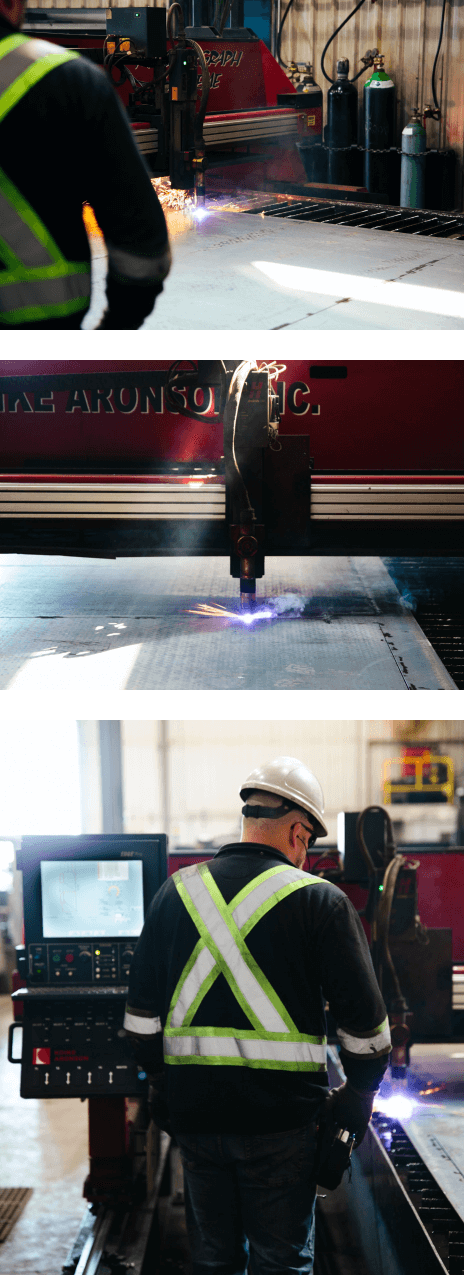

ARC Industries Plasma cutting is an advanced, high-precision method of cutting conductive metals using a powerful arc of ionized gas. But it’s more than just cutting—our Arc Cut Pro 30-D also bevels, drills, taps, and mills parts directly on the table. That means fewer setups, less handling, and faster turnaround.

Whether you need clean base plates, bevelled weld preps, or threaded holes, ARC Plasma is built for speed and accuracy. Perfect for oilfield, industrial, and custom fabrication work. Our team is ready to cut, bevel, and machine your part—start to finish.

Our technicians use the powerful Arc Cut Pro 30-D system—equipped with heavy-duty drilling and advanced beveling features—to process steel, aluminum, and stainless components quickly and precisely:

Table Size: 8 ft × 24 ft — fits large base plates and long beams

Plasma cutting:

Plasma bevel Cutting: up to ≈ 52° for perfect weld preps.

Oxy-acetylene flame cutting: mild-steel plate to ≈ 4 in. (thicker pending trials)

Carbide drilling, rigid tapping, helical milling: holes and threads to 2 in. Ø

Structural profiles: angle, channel, beam, HSS — up to 8 in. tall

You get plate, sheet, and structural parts cut and machined without moving off the table.

Quick Specs Recap

MATERIALS WE PROCESS

If it welds, we can cut it!

We accept DXF, DWG, STEP, and PDF files. Just upload your drawing and we’ll take care of the rest—from quoting to final cut.

1. Upload your file (DXF, DWG, STEP, or PDF

2. Get a same-day quote with a delivery date

3. Nesting and programming to reduce waste

4. Cut, bevel, drill, tap — all in one setup

5. Final QC and shipping anywhere in Alberta or beyond

Yes—our Arc Cut Pro 30-D handles cutting, beveling, drilling, tapping, and milling all in one setup. That means fewer steps and quicker turnaround.

We handle everything from oilfield skids and base plates to stair stringers, header adapters, and OEM sub-assemblies. If it’s on your drawing list, we can probably do it.