When it comes to metal processing, choosing the proper technique is key to the success of your project. Whether you’re working on a small-scale DIY task or a large industrial project, the type of metal processing you select can impact the final outcome. At Brooks Industrial Metals, we’re proud to offer a range of metal processing services to meet your needs.

In this article, we’ll take a closer look at the most common metal processing techniques to help you decide which method is best suited for your project!

Types of Metal Processing Techniques

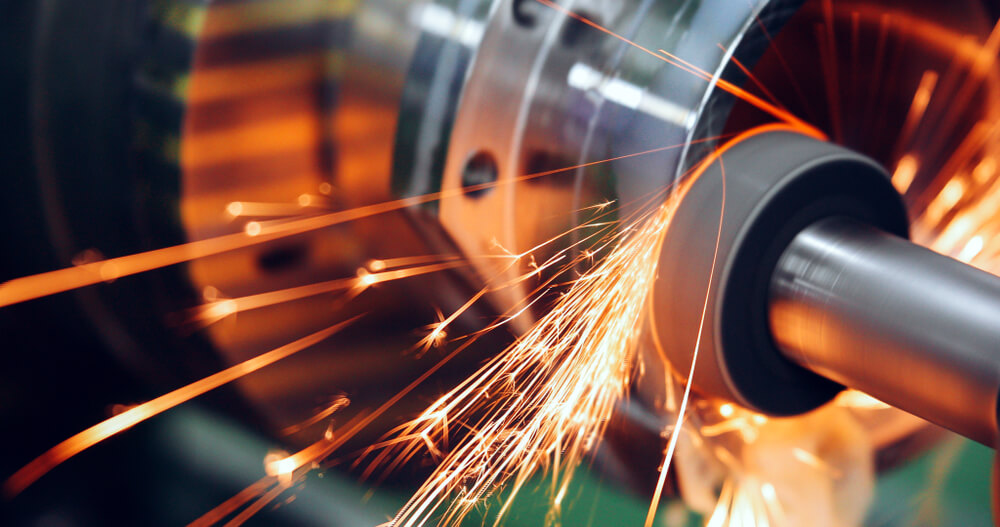

1. Cutting

Cutting is one of the most basic and commonly used metal processing techniques. This process involves removing unwanted material from a metal workpiece to achieve the desired shape or size. Cutting methods range from simple hand tools to advanced machines like laser cutters, shears, and saws. Depending on your project’s complexity, cutting may be the first step in preparing your metal for further processing.

At Brooks, we offer Bandsaw and plasma-cutting solutions to meet your specific metal-cutting requirements. For more on this, check out our blog on the 5 key benefits of metal laser cutting services.

2. Bending

Bending is ideal for projects that require shaping metal into angles or curves. This process uses a press brake to manipulate the metal into the desired form without cutting or removing material. Bending is essential in the construction, automotive, and manufacturing industries to create structural components like beams or brackets.

3. Rolling

Rolling involves passing metal through a series of rollers to reduce thickness, increase length, or create a uniform surface. This technique is commonly used to produce metal sheets, bars, and pipes. Rolling is especially useful for projects that require large quantities of metal material to be processed efficiently.

4. Punching

Punching is a metal processing technique that involves creating holes in metal sheets. This method is commonly used in the production of metal parts, such as brackets or machine components. A punch press can create clean and precise holes.

5. Shearing

Shearing is another cutting technique that focuses on straight-line cuts without the need for a heat source. It is perfect for trimming edges or cutting large sheets of metal into smaller, manageable pieces. This process is highly efficient, making it an excellent choice for projects that require uniform cuts with minimal material waste.

6. Forming

Forming processes involve shaping metal parts by deforming them without removing material. This includes techniques like stamping, which is used to create intricate patterns or shapes in metal sheets. Forming is essential for industries that produce components in large quantities, like automotive manufacturing.

Which Metal Processing Technique is Right for You?

The type of metal processing you choose will depend on several factors, including the size of your project, the type of metal you’re using, and your desired final result.

At Brooks Industrial Metals, we offer a wide range of metal processing services, including:

- Cutting

- Bending

- Punching

- Rolling

- Shearing

- Forming

Each of these techniques can be tailored to suit the specific needs of your project. Our metal processing department utilizes the most modern CNC (computer numerically controlled) equipment and technology. By combining this technology with our profoundly experienced staff, we can provide customers with fabricated metal products that are both precise and cost-effective.

Contact us today to learn more!