In the manufacturing world, there’s no room for ambiguity when it comes to quality. For those producing metal parts, which find their way into countless products, quality control is vital. It’s not just about catching defects but ensuring parts meet design specifications and work as intended. A solid quality control program can keep manufacturing on track, within budget, and steer clear of costly recalls or safety issues.

The success of the final product often hinges on the quality of its components, making it essential to choose a parts provider who understands the stakes. In this article, we’ll dive into the essentials of quality control, from defining part requirements to the tools and inspections needed to achieve consistent results with premium metal supply.

Rigorous Quality Checks

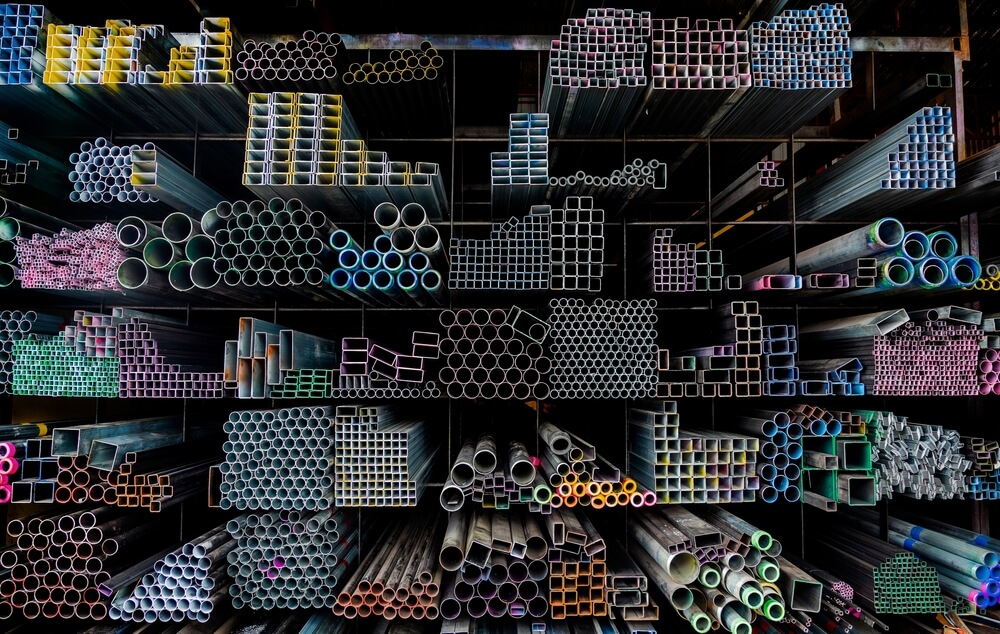

Every reliable metal supplier recognizes the importance of stringent quality checks. These inspections typically encompass:

- Visual Inspections – The initial phase where any glaring discrepancies or deformities are spotted and rectified.

- Dimensional Testing – Ensuring the dimensions of the supplied metals are consistent with the specifications.

- Mechanical Property Testing – Verifying the strength, elasticity, and other mechanical properties of the metal.

- Chemical Composition Analysis – Confirming that the metal’s alloying elements are consistent with the prescribed standards.

- Non-Destructive Testing – Techniques such as ultrasonic and radiographic testing that help detect internal flaws without damaging the metal.

Certifications

The certifications held by a metal supplier are more than just pieces of paper. They serve as a testament to their commitment to excellence.

When a supplier holds internationally recognized certifications, it guarantees that their operational processes and final products adhere to global standards. From ISO certifications to specific industry approvals, these badges ensure that the metals supplied are of top-notch quality, have been processed under controlled conditions, and meet the desired standards.

The Importance of Premium Quality Metals

Here are reasons why premium quality metals are critical:

- Durability – High-quality metals last longer, reducing the frequency of replacements and, consequently, the costs.

- Safety – Premium metals are less likely to fail under stress, ensuring the safety of structures, vehicles, or any application they’re used in.

- Performance – Superior quality metals perform better under various conditions, be it extreme temperatures, pressures, or corrosive environments.

- Economic Viability – Investing in premium metals can lead to savings in the long run, thanks to reduced maintenance and replacement costs.

Reliable Metal Supplier in Brooks

The next time you’re on the lookout for a metal supplier, remember to prioritize quality. By doing so, you ensure the durability, safety, and efficiency of your projects. And with suppliers like Brooks Industrial Metals leading the charge, you’re assured of getting the gold standard in metal supply.

Brooks Industrial Metals is your ideal metal supplier source. We provide various high-quality products at competitive prices, such as carbon steel, stainless and aluminum products, including welding equipment and gases. As a family-run company for over five decades, we have focused on providing tailored products to accomplish our client’s demands.

Contact our team of professionals to get metal supplies, welding products and gas solutions that cater to your precise needs!