Laser cutting offers several advantages over traditional cutting methods, including increased speed, flexibility, and the ability to cut complex shapes with high precision. It is widely used in industries such as automotive, aerospace, and electronics for various applications, including the production of components, signage, and decorative items.

Laser cutting is a highly precise and efficient metal processing technique that utilizes a focused laser beam to cut through various types of metals. It has gained popularity in the industrial sector due to its ability to deliver clean and accurate cuts with minimal material wastage.

Share Your Cutting Requirements

Contact us with details about your project, including the type of metal, thickness, dimensions, and specific cutting requirements. Our team will assess your needs to determine the best approach for your laser cutting project.

Receive a Custom Quote

Based on the provided information, we’ll offer a customized quote outlining pricing and timelines for your laser cutting project. Our goal is to ensure transparency and alignment with your expectations.

Start Your Project

Upon approval, we initiate the laser cutting process using our advanced equipment, delivering precise and clean cuts promptly and to your exact specifications.

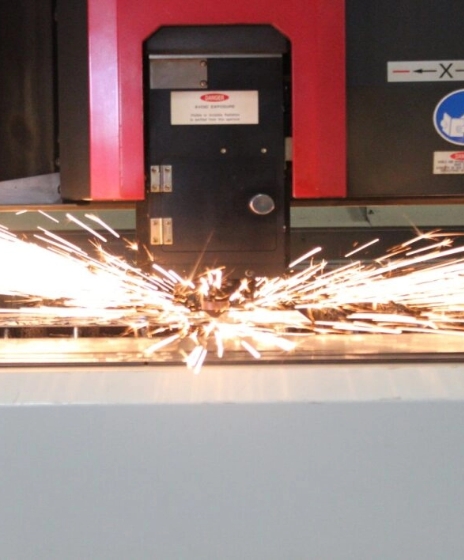

Our Machine – Mitsubishi 2.7 KW Dual Shuttle Table

The laser equipment we use at Brooks Industrial Metals Ltd offers maximum productivity and quick turnaround time without compromising quality. We use:

The CNC laser machine enables increased production times with greater precision and accuracy, minimal operator intervention, and reduced human error. We focus on attention to detail and produce quality products of various designs, shapes, and sizes.

Laser cutting works by directing a high-powered laser beam onto a metal surface. The laser beam generates intense heat that melts or vaporizes the material, creating a narrow and precise cut. Computer-controlled mirrors or lenses determine the cutting path, allowing intricate designs and shapes to be achieved with exceptional accuracy.

We can laser cut mild steel up to 3/8 inch, stainless steel up to 5/16 inch, and aluminum up to 5/16 inch.

The laser cutting process at Brooks Industrial Metals maintains a precision of +/- 0.003 inches.

We are equipped with the Mitsubishi 2.7 kW Dual Shuttle Table. The laser cutter can handle materials up to 5 feet by 10 feet.